500

Throughput

LCM/H)

1332

POWER

(KW/HP)

Drum diameter (mm)

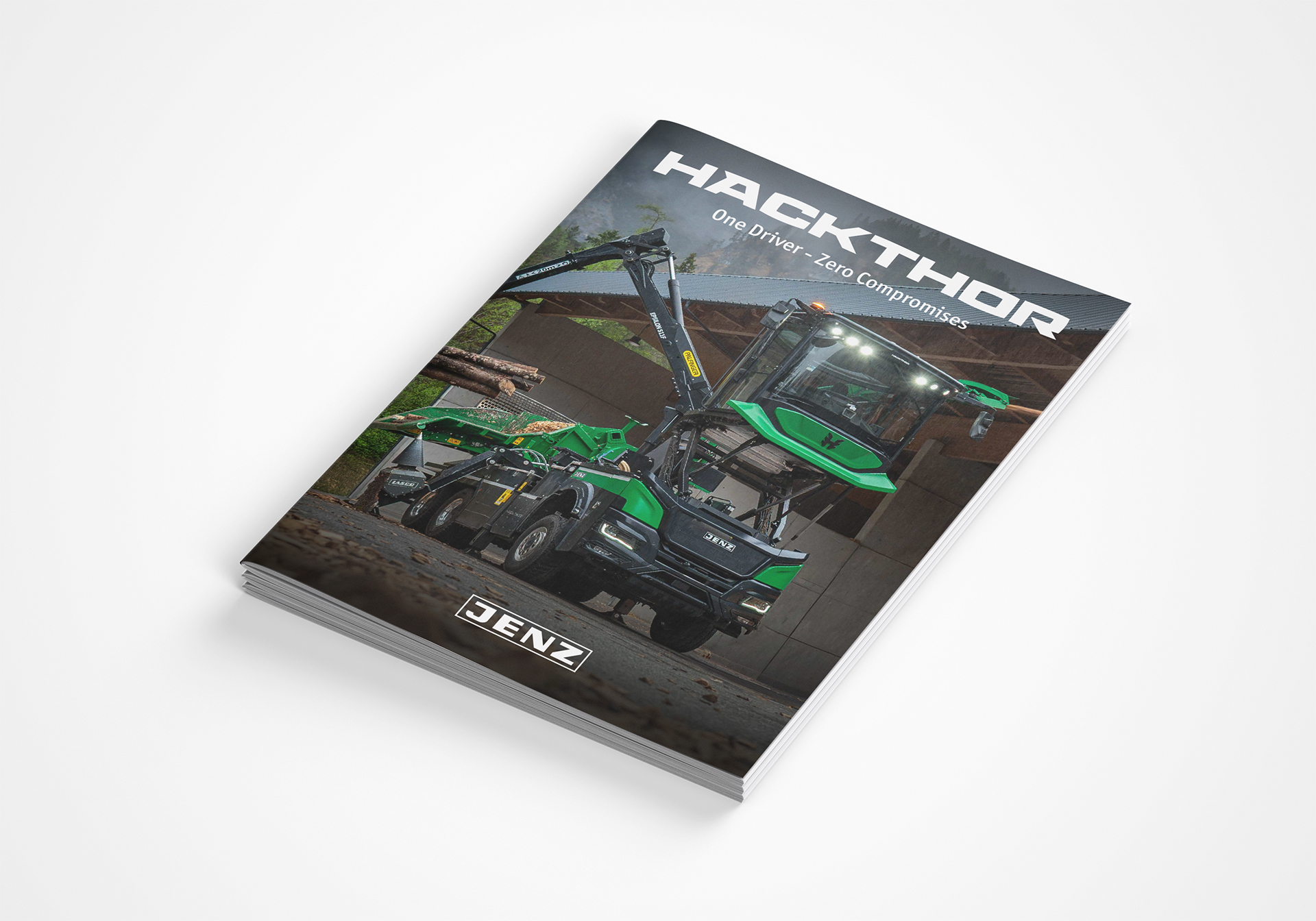

One Driver – Zero Compromises

The Hackthor, a technological milestone that takes comfort, productivity and efficiency to a new level.

With its sophisticated concept, the HACKTHOR is aimed at real professionals - drivers who want to perform at their best day after day without compromising. With the HACKTHOR, JENZ has developed a machine that not only impresses with its enormous shredding power, but also scores highly in terms of user-friendliness, safety and economy.

The innovative 3-zone cabin concept ensures smooth switching between driving, chipping and maintenance - without any detours. The viewing window and crane slewing range are optimized so that the driver always has full control. And all this on an economical truck chassis with mechanical steering - robust, reliable, efficient.

The Hackthor is not a vision, it is reality. And ready for any job.

The innovative 3-zone cabin concept

Uniquely good

The self-propelled chippertrucks are the ideal choice for companies that value economy, ease of use and flexibility. The chippers are fuel-efficient and take the burden off the driver thanks to ergonomic cab concepts and intelligent maintenance and control solutions

More Details

Hackthor HEM 583 |  Hackthor HEM 593 |  Hackthor Hybrid | |

Performance | |||

| Maximum throughput ca. (lcm/h) | 270 | 300 | 500 |

Draw-in | |||

| Draw-in width (mm) | 1200 | 1400 | 1200 |

| Draw-in height (mm) | 680 | 680 | 900 |

Grinding unit | |||

| Rotor diameter | 820 | 820 | 1040 |

Material discharge | |||

| Blower/Conveyor belt | Blower | Blower | Blower |

| hydraulic/mechanic | hydraulic | hydraulic | hydraulic |

Main drive | |||

| Power (kW/hp) | 382/520 | 382/520 | 979/1332 |

| Power (kW/hp) | 382/520 | 382/520 | 979/1332 |

| System power (in kW/hp) | 382/520 | 382/520 | 979/1332 |

Chassis | |||

Weight | |||

| Weight in t * equipment-dependent | 27,1 | 27,7 | 32 |