160

throughput

(lcm/h)

420

Power consumption

(HP)

820

drum diameter

(mm)

Compact Economical Powerful

With the HEM 5600 Z, JENZ is specifically closing a gap in its own portfolio: Between the proven 80 cm intake (e.g. HEM 5400 Z) and the large-volume 120 cm model HEM 583 Z, the HEM 5600 Z complements the range as a powerful mid-range solution - with low investment costs at the same time.

Powered by the PTO shaft of a tractor up to 400 hp, the HEM 5600 Z offers a 100 cm wide feed, an 820 mm chopping drum and an optional larger crane than the HEM 5400 Z - perfect for anyone who wants to handle more material in less time without having to invest in large-scale technology.

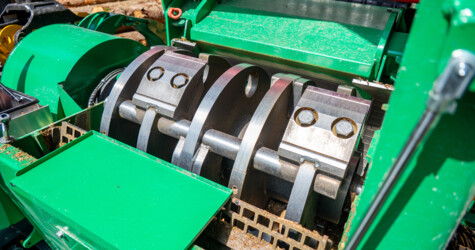

The outstanding feature of the HEM 5600 Z is the standard D1.2 rotor with a diameter of 820 mm and 20 to 42 mm adjustable front grip without side discs. This ensures extremely smooth running and enables optimum chipping even with low drive power. The 100cm wide infeed enables higher throughput rates.

Uniquely good

JENZ wood chipper are the ideal choice for companies that value economy, ease of use and flexibility. The chippers are fuel-efficient and take the burden off the driver thanks to ergonomic cab concepts and intelligent maintenance and control solutions.

More Details

HEM 5600 Z | |

Performance | |

| Maximum throughput ca. (lcm/h) | 160 |

Draw-in | |

| Draw-in (WxH in mm) | 1000 x 700 |

Grinding unit | |

| Rotor diameter | 820 |

Material discharge | |

| Blower/Conveyor belt | Blower |

| hydraulic/mechanic | mechanic |

Main drive | |

| Performance consumption (in kW/hp) | 140 - 309 / 190 - 420 |

Weight | |

| Weight in t * equipment-dependent | 12,5 |

Transport dimensions | |

| Dimensions transport position* (LxWxH in m) * equipment-dependent | 5,70 x 2,55 |